Patented Platen Straightener Feature

Rapid-Air straighteners are unmatched at smoothing ripples, removing coil set, and setting the amount and direction of curvature.

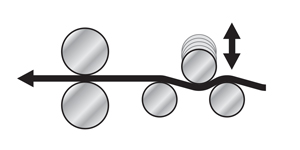

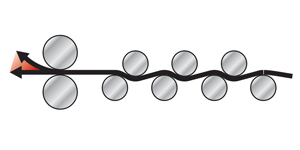

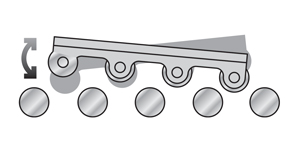

The traditional straightener operates by vertically adjusting a straightening roll between two opposing rolls as illustrated in Figure 1 below. Notice that the rolls are effective at smoothing ripples in material and not very effective at removing coil set.

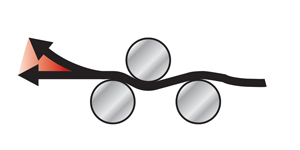

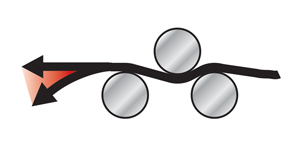

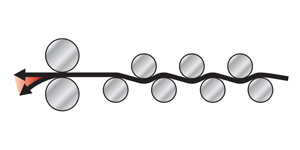

Now see what happens when the rollers can be adjusted forward and backward and up and down as in the patented Rapid-Air straighteners. Figure 2 illustrates a forward position of the straightening roll with the resulting upward curve of material. Figure 3 illustrates a rear position of the straightening roll with the resulting downward curve to the material. Notice that the sharpest bend occurs where two rolls are close together. The degree of bend can be adjusted by a combination of vertical and horizontal adjustments.

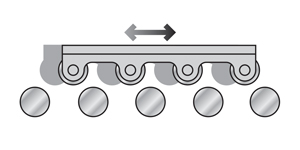

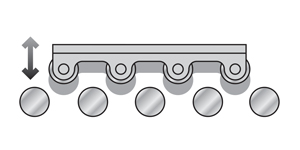

Additional rolls are added to better smooth ripples in material as illustrated in Figures 4 & 5 below.

Six-way upper roll adjustment:

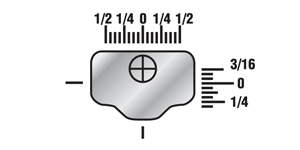

After manufacturing straighteners with vertically adjustable rolls for many years, Rapid-Air developed and patented the adjustable platen type straightener as illustrated in Figure 6.

Roll position indicators are built into the side of the adjustable platen – eliminates the need

for dial-type indicators.

Advantages:

The high degree of flexibility afforded by the adjustable platen design provides a predictable straightening method for a wide variety of materials and takes a lot of the “Black Magic” out of pressroom straightener setup. The reduction in the flexing and distortion of the strip of material and the reduction of the straightening power required allows this design to be effective with heavy materials. Additionally, the ability to place rolls in a proper close proximity allows effective straightening with very thin materials.

Roll diameter:

The smaller the roll diameter in a straightener, the better it is able to remove distortions in the strip of material. But this factor is compromised by the requirement of larger rolls in wider models of straighteners in order to prevent deflection of the rolls themselves. Rapid-Air straighteners are designed to optimize all factors (including number of rolls, diameter and position) within the published material capacities and specifications for each model.

Counter-balanced, swing-open top:

Rapid-Air pioneered the swing-open top in order to facilitate cleaning of rolls and threading of a new strip of material. For convenience and safety, each top is counter-balanced and held in the open position until it is clamped for operation. Roll adjustment settings are maintained when the top is closed and locked.

Outperforms competitive makes.

Within rated thickness capacities Rapid-Air straighteners will outperform competitive makes that rely on traditional vertically adjustable rolls or those with simple two-point bank adjustment – including many of the expensive 17 or 21 roll varieties.